Customized Compac Sheets

Price 550 INR/ Square Foot

MOQ : 100 Square Foots

Customized Compac Sheets Specification

- Resistance

- Water & Termite Resistant

- Thickness

- 3mm, 6mm, 12mm, 18mm (customizable) Millimeter (mm)

- Edge

- Square Edge, Customized Edge Available

- Glue

- Other

- Product Type

- Customized Compac Sheets

- Material

- Wood Based Panels / Engineered Wood

- Surface Finishing

- Other

- Application

- Other

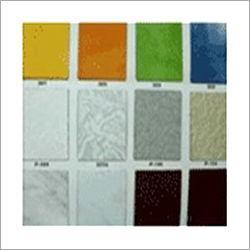

- Color

- Other

- Size

- 1220 mm x 2440 mm (custom sizes available)

- Density

- 850 Gram per cubic centimeter(g/cm3)

- Moisture Content

- 5-8%

- Feature

- Smooth Surface, High Durability, Customizable Sizes

- Grade

- Exterior / Interior Grade Available

- UV Resistance

- Optional

- Load Bearing Capacity

- High

- Formaldehyde Emission

- E1/E0 standard

- Fire Rating

- Available on request

Customized Compac Sheets Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 10000 Square Foots Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- Assam, Himachal Pradesh, Manipur, Meghalaya, Arunachal Pradesh, Andaman and Nicobar Islands, , South India, Central India, East India, West India, Andhra Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, North India, Telangana, All India

About Customized Compac Sheets

Since inception of our company, we are engaged in catering to the varied needs of the clients by bringing forth massively acknowledged Compac Sheet. This is extensively used for construction of ceilings, windows & furniture, partition, it is further installed in toilets, passages, kitchens, homes, bathrooms, wall drops and bedrooms.

- Compac Sheet of our company is massively used by variegated famous hotels, resorts, malls, restaurants and offices.

- This is reliable, durable, termite proof, water resistance, fire resistance and chemical resistance.

Versatile Applications Across Projects

Compac Sheets are engineered for a variety of settings including interior decoration, furniture manufacturing, partitions, and wall cladding. Their high durability, standardized density, and water-resistant properties ensure optimal performance in both residential and commercial environments. Customized sizes and finishes make them a preferred choice for unique design visions.

Tailored to Your Requirements

Our sheets are available in multiple thicknesses3mm, 6mm, 12mm, and 18mmand can be further customized for specific project specifications. You can choose between matte, glossy, or textured finishes, as well as standard or custom edge options. Fire rating, UV resistance, and anti-bacterial treatments can be included upon request to enhance functionality.

Exceptional Performance and Sustainability

Manufactured with E1/E0 formaldehyde emission standards and giving a choice between melamine or phenol formaldehyde glue, Compac Sheets support a healthier indoor environment. Their engineered composition guarantees high abrasion resistance, solid load-bearing capacity, and consistent moisture content, contributing to product longevity and safe usage.

FAQs of Customized Compac Sheets:

Q: How can Compac Sheets be customized for my project?

A: Compac Sheets can be tailored in terms of size, thickness (3mm to 18mm), surface finish (matte, glossy, textured), edges, color, and pattern. Special functional features like fire rating, anti-bacterial surface, and UV resistance can also be added upon request to match your projects requirements.Q: What benefits do Compac Sheets offer over traditional wood panels?

A: These engineered sheets feature high load-bearing capacity, resistance to abrasion, water, and termites, and a structurally solid or calibrated core. They offer enhanced durability, precise tolerance (0.2 mm), low formaldehyde emission, and can be finished in a variety of visual styles and edges.Q: Where are Compac Sheets most effectively used?

A: Compac Sheets are ideal for interior decoration, furniture, partition panels, and wall cladding in homes, offices, and commercial spaces. Theyre suitable for applications that require high durability and resistance to moisture or wear.Q: What is the process for ordering customized Compac Sheets?

A: Start by contacting us with your requirements regarding thickness, surface finish, color, edge design, and desired special features. We will provide guidance, samples if needed, and a quote before initiating manufacturing to ensure the sheets match your specifications.Q: When should I opt for additional features like UV resistance or fire rating?

A: Select UV resistance for projects exposed to sunlight or harsh lighting, and request fire rating for locations that demand added safety, such as public buildings or areas prone to higher fire risk. These options can be specified during the ordering process.Q: How do Compac Sheets contribute to health and safety?

A: With low formaldehyde emission (E1/E0 standard), moisture-resistant structure, and anti-bacterial surface options, Compac Sheets help maintain healthier indoor air quality and hygiene, making them a safe choice for sensitive environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Compac Sheets Category

Compac Furniture Sheets

Price 495 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Resistance : Moisture Resistant, Termite Resistant, Borer Resistant

Size : 8x4 feet (2440mm x 1220mm)

Surface Finishing : Other, Matt / Gloss / Textured

Thickness : 2.5 mm to 25 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS